AWS-Certified Welding for Aluminum, Stainless Steel, & Carbon Steel

Expert MIG and TIG welding services with AWS-certified precision. From aluminum and stainless steel to carbon and galvanized steel, Preferred Metal Products delivers high-strength, high-quality welds for any project.

Powder Coating, Electropolishing & Anodizing for Superior Protection

Premium surface treatments for durability and aesthetics. Our powder coating, electropolishing, and anodizing solutions provide enhanced protection, strength, and custom finishes for any industry.

Precision, Reliability & Consistency in Every Product

ISO 9001:2015-certified metal fabrication with strict quality control. Every product undergoes thorough inspection, ensuring precision, durability, and reliability from start to finish.

Advanced Multi-Angle Bending with Tight Tolerances

Superior Metal Bending with Tight Tolerances – Our advanced press brakes and state-of-the-art technology ensure consistent accuracy within ¼ of a degree. Learn how we can support your custom fabrication needs today.

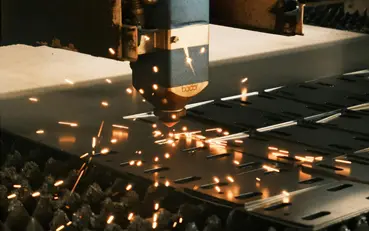

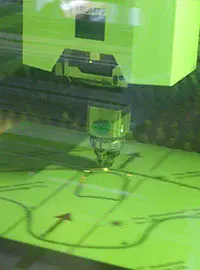

High-Speed, High-Precision Metal Cutting with Tight Tolerances

Unparalleled precision and efficiency in laser cutting. Whether you’re working with steel, stainless steel, or aluminum, our Trumpf 1030 laser technology ensures exceptional quality with minimal post-processing.

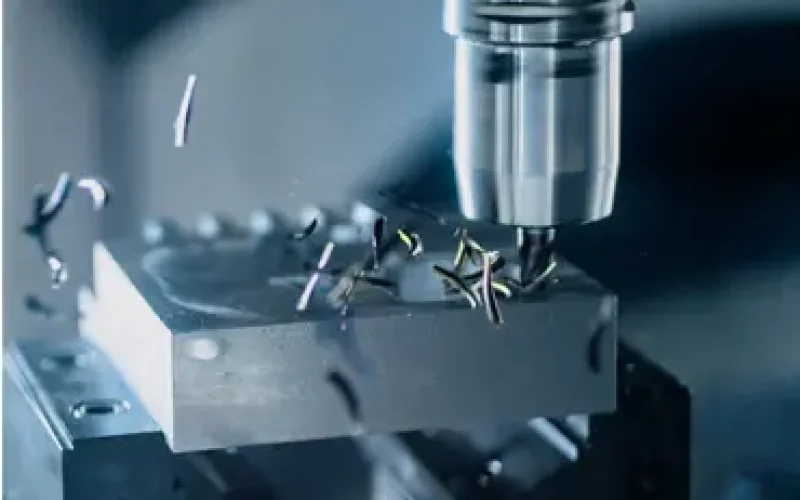

Precision, Speed, and Efficiency for High-Quality Metal Fabrication

Enhance your production efficiency with high-speed metal punching and marking solutions that deliver unmatched precision, speed, and cost-effectiveness. Our Trumpf 1000 Punch Press ensures rapid part production with minimal setup time for industries demanding high-quality metal components.

High-Quality Aluminum & Alloy Extrusion Work

Expert extrusion cutting with precision and efficiency. Using chop saws for aluminum and cold saws for hard alloys, we deliver high-quality, clean cuts for any industry.

Custom Hardware Insertion & Riveting for Secure, Reliable Assemblies

Expert assembly and hardware insertion services with precision and reliability. Using Autosert Machines, AVK tools, and riveting solutions, we ensure secure, high-quality assemblies for any industry.

We provide high-accuracy metal cutting and shaping, including laser cutting for clean edges, metal punching for precise cutouts, metal shearing for straight-line cuts, and metal bending for complex forms.

Our expert welding and fabrication services include MIG & TIG welding for strong, durable joints, custom metal bending for precise designs, and development & prototyping for unique and custom solutions.

Our assembly and prototyping services include hands-on builds, precise component integration, and iterative testing to refine, validate, and optimize product designs before moving into full production.

Custom & High-Volume Manufacturing with Unmatched Quality

Preferred Metal Products has been a leader in precision metal fabrication since 1989, offering high-quality metal parts and components at competitive prices. With a 15,000-square-foot facility, state-of-the-art equipment, and a team of ISO 9001:2015-certified experts, we deliver custom and production fabrication solutions for industries such as HVAC, electronics, construction, automotive and marine. Whether you need laser cutting, CNC milling, punching, bending, welding, or finishing services, we have the expertise to bring your projects to life.

Located in a modern industrial area with major highway access, we offer complete design assistance for metal enclosures, structural components, and custom prototypes. Our commitment to cutting-edge technology, precision, and customer satisfaction sets us apart. Let us be your trusted partner for all your metal fabrication needs.

Over 35 Years of Expertise in precision metal fabrication.

15,000 sq. ft. Facility with advanced manufacturing capabilities.

ISO 9001:2015 Certified for strict quality control and consistency.

Laser Cutting, CNC Milling, and High-Speed Punching for precision components.

Custom Metal Bending, Welding, and Assembly to meet your specifications.

Electropolishing, Powder Coating, and Specialized Finishing Services.

Prototyping & Design Assistance to bring concepts to reality.

Fast Turnaround Times.

Industries Served: HVAC, Electronics, Construction, Automotive, & Marine.

At Preferred Metal Products, we do more than fabricate — we deliver smart, reliable solutions that enhance efficiency, durability, and performance. With advanced manufacturing technology, precise engineering, and expert craftsmanship, we specialize in medium-scale production that meets the highest industry standards.

From complex parts to repeat runs, our team ensures consistent quality, quick turnaround, and responsive service. Businesses across industries trust us for dependable production, clear communication, and a competitive edge.

Experience superior precision and efficiency with the Trumpf 5170 Press Brake. Featuring automatic tooling, high bending force, and flexible programming, it’s the ideal solution for complex and high-volume production.

The Trumpf 5085 Press Brake delivers high-precision metal bending with advanced CNC controls, customizable tooling, and energy-efficient performance. Perfect for heavy-duty applications.

Experience high-speed punching with precision and efficiency using the Trumpf Trupunch 1000. Designed for versatility and cost savings, this machine enhances your production capabilities.

Experience high-speed, precision laser cutting with the Trumpf 1030 Fiber Optic Laser. Designed for efficiency and versatility, it’s the perfect solution for manufacturers looking to enhance productivity and reduce operating costs.

Cutting-Edge Technology. Unmatched Accuracy. Exceptional Quality.

At Preferred Metal Products, we specialize in high-precision metal fabrication services designed to meet the demands of industrial, commercial, and custom applications. From intricate cuts to high-speed production and complex forming, our advanced capabilities ensure top-tier quality, efficiency, and durability in every project.

High-precision cutting with clean edges and tight tolerances. Our advanced laser cutting technology delivers superior accuracy with minimal material waste, making it ideal for custom and industrial applications.

Fast, cost-effective perforation and shaping for medium-scale production. Our CNC-controlled punching delivers consistent accuracy and quick turnaround—ideal for projects that need quality without the scale of mass manufacturing.

Precision bending and shaping for durable, custom components. From simple bends to intricate geometries, our expert sheet metal forming services ensure structural integrity and a perfect fit for every design.

Fast Turnarounds. Competitive Pricing. Unmatched Quality.