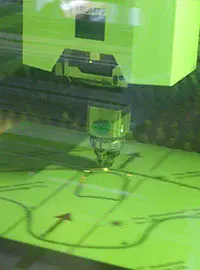

The Trumpf TruLaser 1030 Fiber is a cutting-edge solution for precision metal cutting, engineered for speed, accuracy, and operational efficiency. Equipped with a 3000-watt (3kW) fiber laser source, it supports sheet formats up to 5 feet by 10 feet (60″ x 120″), making it ideal for a broad range of industrial applications.

Designed to process mild steel up to 1 inch, stainless steel up to 0.5 inches, and aluminum up to 0.375 inches, the TruLaser 1030 offers exceptional material flexibility without compromising on cut quality. Its automation-ready design allows for seamless integration with material handling systems, enabling streamlined operations and reduced labor requirements.

With advanced fiber laser technology, the Trumpf 1030 delivers high cutting speeds and tight tolerances, ensuring consistent, clean edges and minimal post-processing across all supported materials. Low maintenance requirements and energy-efficient operation make it a reliable, cost-effective solution for modern fabrication shops focused on productivity and precision.

At Performance Metal Products (PMP), we are committed to delivering state-of-the-art laser cutting solutions that drive efficiency and quality in metal fabrication. Our expertise in precision cutting technology ensures that our clients receive highly accurate and consistent results for every project. With ISO 9001:2015 certification, we adhere to the highest industry standards, guaranteeing reliable performance and exceptional customer service.

Our 14,000-square-foot facility is equipped with the latest metal fabrication technology, including high-speed laser cutting, CNC milling, and automated material handling. Whether you need prototyping or large-scale production, PMP has the capabilities to optimize your manufacturing process, reduce lead times, and enhance product quality.

Discover how the Trumpf 1030 Fiber Optic Laser can revolutionize your production process with unmatched precision, speed, and energy efficiency. Contact Performance Metal Products for a customized solution that meets your specific manufacturing needs.