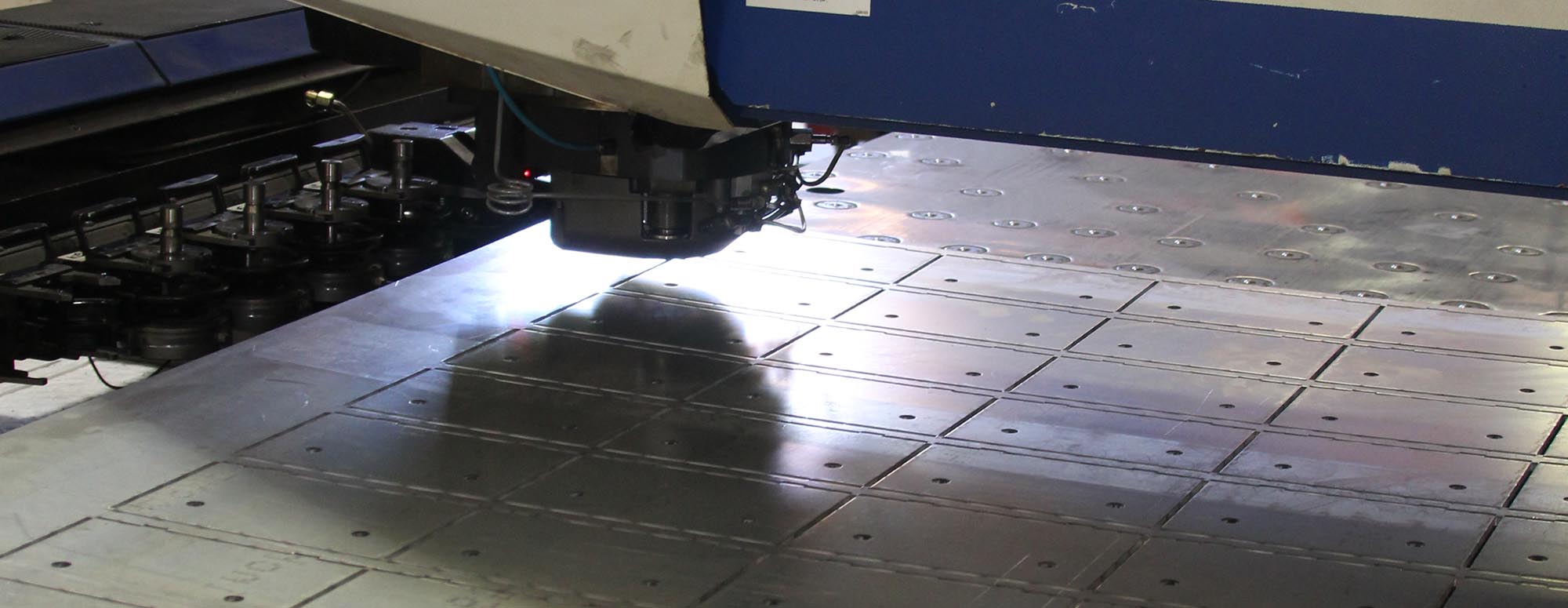

High Speed Marking, Forming and Logo Stamping

Our Trumpf 2020R Punch Press combines high speed and precise accuracy to provide our customers with high quality parts in the fastest time possible. Fast part production requires not only a quick machine, but also minimal setup time. This is achieved because of tool cartridges easily placed in the machine. Tool change is completed in less than half the time of a standard turret. Every tool on the 19 station rail is fully rotational, 360 deg.

Punching rates of up to 7 holes per second on one inch centers and nibbling rates of 900 hits per minute on a 50˝ x 100˝ sheet reduces production time and cost. In addition to standard punching, our Trumpf 2020R is also capable of high-speed marking, forming, and logo stamping.

Trumpf 2020R Punch Press capacity

- .25″ in 4′ x 8′ sheet

- under .25″ in 4′ x 10′ sheet

- Speeds up to 7 holes per second with one inch centers (420 holes per minute).

- Nibbling speeds up to 920 strokes per minute.

- High speed marking at 2200 strokes per minute.

- 360 degree rotation of all tools.

- Accuracy: Repeatability +/- .0012″

- Positioning over entire sheet +/- .004

Manual Punching for Short Run Metal Fabrication

50 ton W.A. Whitney single station punch with programmable gauging. Maximum capacity: 5″ diameter through 7 gauge mild steel. 1 1/2″ diameter through 3/8″ mild steel.

- Punching Flat Bars and Angles.

- Punching in Metals Over 1/4″

USA Made Products

USA Made Products